- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

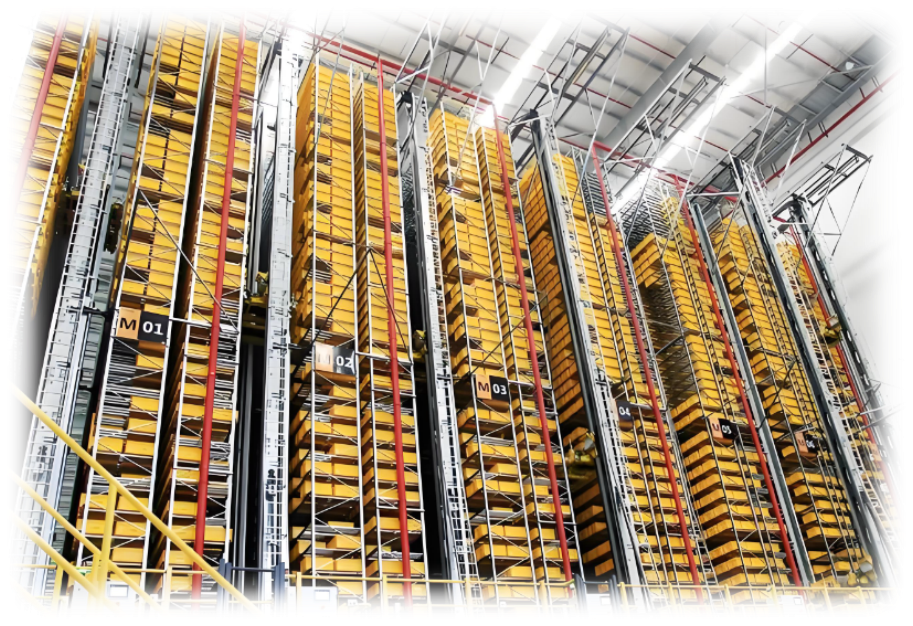

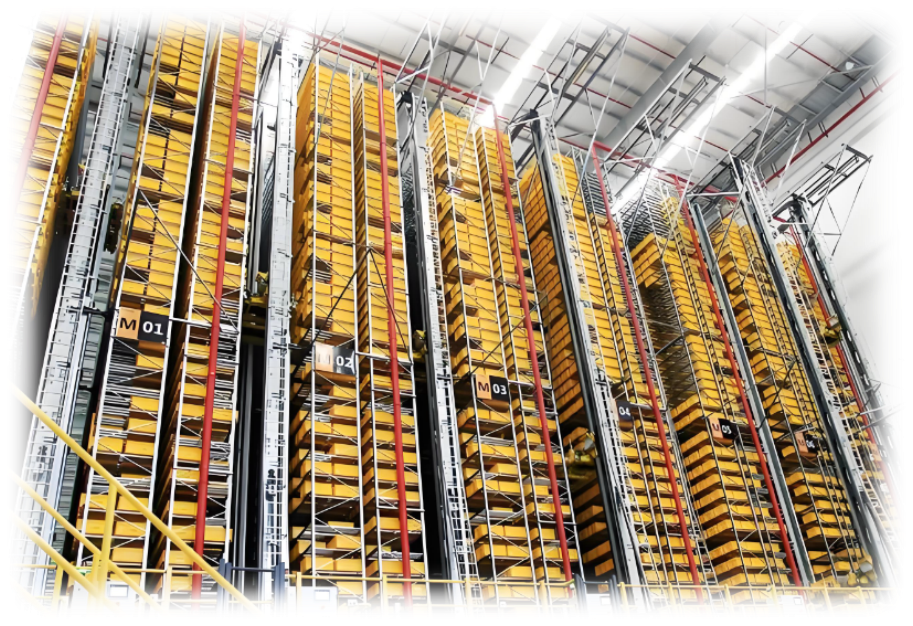

TheMini-Load Automated Storage and Retrieval System (AS/RS) is a precision-engineered solution designed specifically for the storage and retrieval of light-weight, small items. It utilizes high-precision stacker cranes to automatically handle standard plastic containers or cartons within racking, maximizing both space utilization and operational efficiency.

| Availability: | |

|---|---|

| Quantity: | |

The Automated Cantilever Racking (also known as Mini-load ASRS Racking) is a cutting-edge, fully automated storage solution engineered by Nanjing Boracs Logistics Equipment Co., Ltd. Designed specifically for high-density storage of light-weight items in plastic bins or cartons, this system integrates precision stacker cranes with intelligent software to revolutionize warehouse operations. By maximizing vertical space utilization and eliminating manual handling, it delivers unparalleled efficiency for businesses seeking to optimize workflow and inventory management. Compliant with international standards such as FEM, DIN, and ISO, the Automated Cantilever Racking ensures reliable performance across global markets, making it a top choice for e-commerce, 3PL, and manufacturing sectors.

NO. | Item | Parameter / Description |

1 | Container Size | L 400-600mm x W 300-500mm x H 150-300mm (Customized) |

2 | Max. Load per Container | 10kg - 50kg |

3 | System Height | 6m - 25m |

4 | Stacker Crane Speed | Horizontal: 0-180 m/min, Lifting: 0-60 m/min |

5 | Positioning Accuracy | ±2mm ~ ±5mm |

6 | Control Method | Fully automatic, scheduled by WCS/WMS |

Ideal for storing small consumer goods, electronics accessories, and apparel. The Automated Cantilever Racking supports fast order processing and high inventory turnover—key demands of the e-commerce sector.

3PL providers benefit from the system's flexible storage capacity and efficient inventory management. Enabling them to serve multiple clients with diverse product lines while maintaining accuracy.

Stores small electronic components, circuit boards, and spare parts, protecting sensitive items from damage while enabling quick access for production lines.

Unlike traditional storage systems, the Automated Cantilever Racking can reach heights of 6-25 meters, fully tapping into unused vertical space. This design doubles storage density without expanding the warehouse footprint, a critical advantage for facilities with limited floor area. The cantilever structure’s open design also facilitates easy access to stored items, even in high racks.

Equipped with fully automated stacker cranes, the system enables "Goods to Person" picking, eliminating labor-intensive manual tasks. With a picking efficiency of 300-500 boxes per hour per machine, it significantly accelerates order fulfillment. The cranes operate independently, reducing bottlenecks and ensuring continuous workflow.

Integrated with advanced WMS (Warehouse Management System), the Automated Cantilever Racking tracks every container’s location and status in real time. It supports FIFO (First-In-First-Out) inventory rotation and automatic cycle counting, achieving an inventory accuracy rate of over 99.99%. This eliminates stock discrepancies and streamlines inventory control.

The stacker cranes use servo control technology, delivering a positioning accuracy of ±2mm to ±5mm. Equipped with multiple safety sensors and protection devices, the system safeguards personnel, goods, and equipment from collisions or damage. Compliance with global safety standards ensures peace of mind for operators.

The system is designed for light-duty items (10-50kg per container) such as plastic bin-stored products, cartons, electronic components, medical supplies, and small industrial parts. It is not suitable for heavy or oversized loads.

Installation time varies based on warehouse size and system configuration, typically ranging from 4-8 weeks. Our team provides end-to-end project management, including site survey, foundation planning, and operator training, to ensure smooth commissioning.

Routine maintenance includes monthly inspections of stacker crane components, software updates, and lubrication. We offer comprehensive after-sales support, including remote technical assistance, scheduled maintenance, and spare parts supply.

Yes! We offer customized design based on your warehouse dimensions, cargo specifications, throughput requirements, and budget. Container sizes, system height, and control features can all be tailored to your needs.

Pallet Rack Pallet Rack |  Longspan Rack Longspan Rack | ||

Mezzanine Mezzanine |  Very Narrow Aisle Rack Very Narrow Aisle Rack |  Shuttle Radio Rack Shuttle Radio Rack |  Automated Storage Automated Storage |

Wire Mesh Decking Wire Mesh Decking |  Wire Mesh Container Wire Mesh Container |  Steel Pallet Steel Pallet |  Stackable Metal container Stackable Metal container |

The Automated Cantilever Racking (also known as Mini-load ASRS Racking) is a cutting-edge, fully automated storage solution engineered by Nanjing Boracs Logistics Equipment Co., Ltd. Designed specifically for high-density storage of light-weight items in plastic bins or cartons, this system integrates precision stacker cranes with intelligent software to revolutionize warehouse operations. By maximizing vertical space utilization and eliminating manual handling, it delivers unparalleled efficiency for businesses seeking to optimize workflow and inventory management. Compliant with international standards such as FEM, DIN, and ISO, the Automated Cantilever Racking ensures reliable performance across global markets, making it a top choice for e-commerce, 3PL, and manufacturing sectors.

NO. | Item | Parameter / Description |

1 | Container Size | L 400-600mm x W 300-500mm x H 150-300mm (Customized) |

2 | Max. Load per Container | 10kg - 50kg |

3 | System Height | 6m - 25m |

4 | Stacker Crane Speed | Horizontal: 0-180 m/min, Lifting: 0-60 m/min |

5 | Positioning Accuracy | ±2mm ~ ±5mm |

6 | Control Method | Fully automatic, scheduled by WCS/WMS |

Ideal for storing small consumer goods, electronics accessories, and apparel. The Automated Cantilever Racking supports fast order processing and high inventory turnover—key demands of the e-commerce sector.

3PL providers benefit from the system's flexible storage capacity and efficient inventory management. Enabling them to serve multiple clients with diverse product lines while maintaining accuracy.

Stores small electronic components, circuit boards, and spare parts, protecting sensitive items from damage while enabling quick access for production lines.

Unlike traditional storage systems, the Automated Cantilever Racking can reach heights of 6-25 meters, fully tapping into unused vertical space. This design doubles storage density without expanding the warehouse footprint, a critical advantage for facilities with limited floor area. The cantilever structure’s open design also facilitates easy access to stored items, even in high racks.

Equipped with fully automated stacker cranes, the system enables "Goods to Person" picking, eliminating labor-intensive manual tasks. With a picking efficiency of 300-500 boxes per hour per machine, it significantly accelerates order fulfillment. The cranes operate independently, reducing bottlenecks and ensuring continuous workflow.

Integrated with advanced WMS (Warehouse Management System), the Automated Cantilever Racking tracks every container’s location and status in real time. It supports FIFO (First-In-First-Out) inventory rotation and automatic cycle counting, achieving an inventory accuracy rate of over 99.99%. This eliminates stock discrepancies and streamlines inventory control.

The stacker cranes use servo control technology, delivering a positioning accuracy of ±2mm to ±5mm. Equipped with multiple safety sensors and protection devices, the system safeguards personnel, goods, and equipment from collisions or damage. Compliance with global safety standards ensures peace of mind for operators.

The system is designed for light-duty items (10-50kg per container) such as plastic bin-stored products, cartons, electronic components, medical supplies, and small industrial parts. It is not suitable for heavy or oversized loads.

Installation time varies based on warehouse size and system configuration, typically ranging from 4-8 weeks. Our team provides end-to-end project management, including site survey, foundation planning, and operator training, to ensure smooth commissioning.

Routine maintenance includes monthly inspections of stacker crane components, software updates, and lubrication. We offer comprehensive after-sales support, including remote technical assistance, scheduled maintenance, and spare parts supply.

Yes! We offer customized design based on your warehouse dimensions, cargo specifications, throughput requirements, and budget. Container sizes, system height, and control features can all be tailored to your needs.

Pallet Rack Pallet Rack |  Longspan Rack Longspan Rack | ||

Mezzanine Mezzanine |  Very Narrow Aisle Rack Very Narrow Aisle Rack |  Shuttle Radio Rack Shuttle Radio Rack |  Automated Storage Automated Storage |

Wire Mesh Decking Wire Mesh Decking |  Wire Mesh Container Wire Mesh Container |  Steel Pallet Steel Pallet |  Stackable Metal container Stackable Metal container |