- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

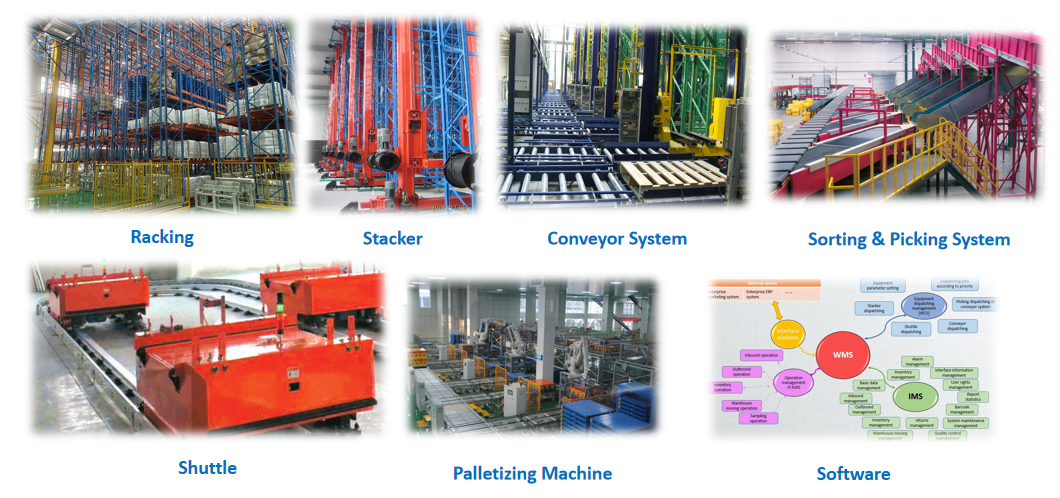

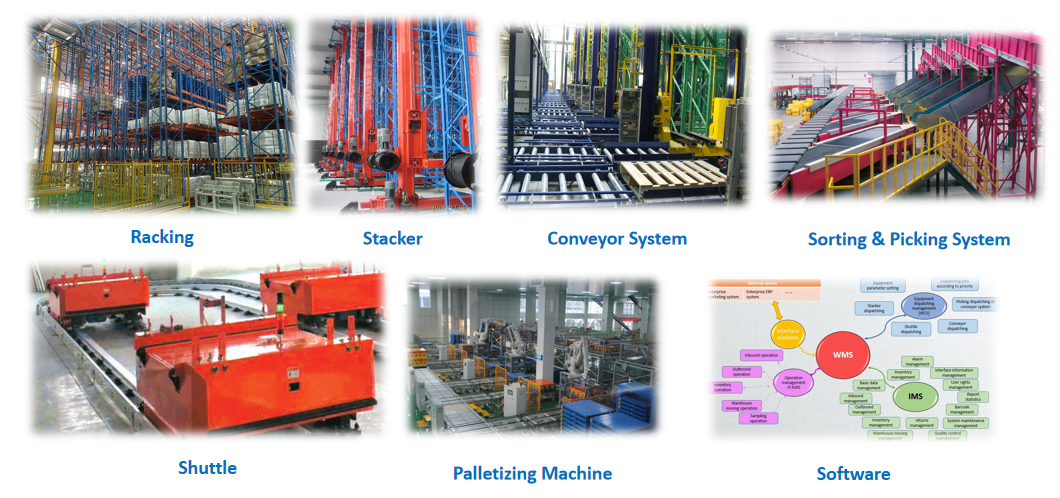

The Automated Pallet Racking System is a core component of modern logistics and warehousing technology, seamlessly integrating traditional heavy-duty racking structures with advanced automated control technologies. Utilizing intelligent equipment such as stacker cranes and shuttles, conveyor system, sorting & picking system, palletizing machine, and under the unified coordination of software systems, this system enables automated storage and retrieval, precise positioning, and efficient management of palletized goods.

| Availability: | |

|---|---|

| Quantity: | |

The Automated Pallet Racking system is a cornerstone of modern intelligent warehousing technology, seamlessly integrating robust heavy-duty racking structures with cutting-edge automated control technologies. This integrated solution leverages intelligent equipment such as stacker cranes, shuttles, conveyor systems, sorting & picking systems, and palletizing machines, all coordinated by advanced software. Designed to optimize the storage and retrieval of palletized goods, it enables 24/7 automated operations, precise positioning, and efficient inventory management—making it a pivotal choice for enterprises aiming to build lights-out warehouses and achieve Industry 4.0 upgrades. Whether for large-scale manufacturing facilities or third-party logistics hubs, this system delivers unmatched efficiency, storage density, and cost savings.

With no reliance on manual shifts, the Automated Pallet Racking system operates continuously, eliminating downtime and maximizing throughput. Its intelligent scheduling ensures rapid handling of inbound and outbound tasks, outperforming traditional manual or semi-automated racking by 300% in operational efficiency.

By leveraging vertical storage potential, this system achieves high-density storage—increasing warehouse space utilization by 50-70% compared to conventional racking. It eliminates wasted aisle space and optimizes vertical height, turning underutilized overhead space into valuable storage capacity.

Equipped with high-precision stacker cranes and shuttle devices, the system achieves positioning accuracy within ±5mm. This precision minimizes product damage and ensures fast access to palletized goods, reducing retrieval time from minutes to seconds.

The Automated Pallet Racking system enforces strict separation of personnel and goods, eliminating the risk of workplace accidents associated with manual handling. Multiple safety protections. Including anti-collision sensors, emergency stop mechanisms, and overload alarms—ensure reliable operation.

By reducing labor dependency by up to 80%, the system cuts staffing costs significantly. It also minimizes product and equipment damage, lowers energy consumption, and optimizes inventory turnover. Delivering long-term cost efficiency for businesses.

Seamless integration with WMS (Warehouse Management System) and ERP software enables end-to-end traceability of goods. Real-time inventory tracking, order management, and data analytics provide full visibility, supporting data-driven decision-making.

| including but not limited to | |

| Manufacturing Industry | Automotive, aerospace, electronics, machinery manufacturing |

| Cold Chain Logistics Industry | Food, pharmaceuticals, fresh produce |

| Consumer Goods Retail Industry | E-commerce, large supermarkets, home improvement and building materials |

| Chemicals Industry | Raw materials, finished goods warehouses Third-Party Logistics* |

| Third-Party Logistics | |

Ideal for automotive, aerospace, electronics, and machinery manufacturing sectors. It stores raw materials, components, and finished products efficiently, supporting just-in-time production and streamlining supply chain workflows.

Perfect for food, pharmaceuticals, and fresh produce storage. Its temperature-resistant design and automated operation ensure goods are handled quickly and safely in low-temperature environments, maintaining product quality.

Suits e-commerce platforms, large supermarkets, and home improvement/building materials retailers. High throughput and dense storage meet the demands of high-volume, fast-turnover inventory—critical for peak shopping seasons.

Reliable for storing chemical raw materials and finished goods. The system’s safety features and sealed operation prevent contamination and ensure compliance with industry regulations.

Adapts to the diverse needs of 3PL providers, handling multiple clients, product types, and order profiles. Its flexibility and scalability make it a versatile solution for dynamic logistics environments.

Installation duration ranges from 4 to 12 weeks, depending on warehouse size, system complexity, and customization requirements. The process includes site survey, foundation planning, equipment installation, commissioning, and final acceptance.

Scheduled maintenance is recommended every 6 months, including equipment inspection, lubrication, and software updates. We provide remote technical support 24/7, and on-site service for emergency issues to ensure uninterrupted operation.

Yes. Our engineering team designs tailor-made solutions based on your warehouse dimensions, cargo specifications (weight, size), throughput requirements, and budget—ensuring optimal performance and space utilization.

Absolutely. The Automated Pallet Racking system supports seamless integration with most existing WMS, ERP, and MES systems. Our technical team ensures smooth data synchronization and workflow alignment.

Yes. All components adhere to global standards such as FEM (European Material Handling Federation), DIN (German Institute for Standardization), ISO (International Organization for Standardization), and CE certification—guaranteeing safe and reliable operation worldwide.

Designed for enterprises pursuing high efficiency, high-density storage, and low operational costs, it is an ideal choice for building "lights-out" warehouses and achieving Industry 4.0 upgrades. We are committed to providing global customers with stable, reliable, and technologically advanced automated warehousing solutions. |

|

Pallet Rack Pallet Rack |  Longspan Rack Longspan Rack | ||

Mezzanine Mezzanine |  Very Narrow Aisle Rack Very Narrow Aisle Rack |  Shuttle Radio Rack Shuttle Radio Rack |  Automated Storage Automated Storage |

Wire Mesh Decking Wire Mesh Decking |  Wire Mesh Container Wire Mesh Container |  Steel Pallet Steel Pallet |  Stackable Metal container Stackable Metal container |

The Automated Pallet Racking system is a cornerstone of modern intelligent warehousing technology, seamlessly integrating robust heavy-duty racking structures with cutting-edge automated control technologies. This integrated solution leverages intelligent equipment such as stacker cranes, shuttles, conveyor systems, sorting & picking systems, and palletizing machines, all coordinated by advanced software. Designed to optimize the storage and retrieval of palletized goods, it enables 24/7 automated operations, precise positioning, and efficient inventory management—making it a pivotal choice for enterprises aiming to build lights-out warehouses and achieve Industry 4.0 upgrades. Whether for large-scale manufacturing facilities or third-party logistics hubs, this system delivers unmatched efficiency, storage density, and cost savings.

With no reliance on manual shifts, the Automated Pallet Racking system operates continuously, eliminating downtime and maximizing throughput. Its intelligent scheduling ensures rapid handling of inbound and outbound tasks, outperforming traditional manual or semi-automated racking by 300% in operational efficiency.

By leveraging vertical storage potential, this system achieves high-density storage—increasing warehouse space utilization by 50-70% compared to conventional racking. It eliminates wasted aisle space and optimizes vertical height, turning underutilized overhead space into valuable storage capacity.

Equipped with high-precision stacker cranes and shuttle devices, the system achieves positioning accuracy within ±5mm. This precision minimizes product damage and ensures fast access to palletized goods, reducing retrieval time from minutes to seconds.

The Automated Pallet Racking system enforces strict separation of personnel and goods, eliminating the risk of workplace accidents associated with manual handling. Multiple safety protections. Including anti-collision sensors, emergency stop mechanisms, and overload alarms—ensure reliable operation.

By reducing labor dependency by up to 80%, the system cuts staffing costs significantly. It also minimizes product and equipment damage, lowers energy consumption, and optimizes inventory turnover. Delivering long-term cost efficiency for businesses.

Seamless integration with WMS (Warehouse Management System) and ERP software enables end-to-end traceability of goods. Real-time inventory tracking, order management, and data analytics provide full visibility, supporting data-driven decision-making.

| including but not limited to | |

| Manufacturing Industry | Automotive, aerospace, electronics, machinery manufacturing |

| Cold Chain Logistics Industry | Food, pharmaceuticals, fresh produce |

| Consumer Goods Retail Industry | E-commerce, large supermarkets, home improvement and building materials |

| Chemicals Industry | Raw materials, finished goods warehouses Third-Party Logistics* |

| Third-Party Logistics | |

Ideal for automotive, aerospace, electronics, and machinery manufacturing sectors. It stores raw materials, components, and finished products efficiently, supporting just-in-time production and streamlining supply chain workflows.

Perfect for food, pharmaceuticals, and fresh produce storage. Its temperature-resistant design and automated operation ensure goods are handled quickly and safely in low-temperature environments, maintaining product quality.

Suits e-commerce platforms, large supermarkets, and home improvement/building materials retailers. High throughput and dense storage meet the demands of high-volume, fast-turnover inventory—critical for peak shopping seasons.

Reliable for storing chemical raw materials and finished goods. The system’s safety features and sealed operation prevent contamination and ensure compliance with industry regulations.

Adapts to the diverse needs of 3PL providers, handling multiple clients, product types, and order profiles. Its flexibility and scalability make it a versatile solution for dynamic logistics environments.

Installation duration ranges from 4 to 12 weeks, depending on warehouse size, system complexity, and customization requirements. The process includes site survey, foundation planning, equipment installation, commissioning, and final acceptance.

Scheduled maintenance is recommended every 6 months, including equipment inspection, lubrication, and software updates. We provide remote technical support 24/7, and on-site service for emergency issues to ensure uninterrupted operation.

Yes. Our engineering team designs tailor-made solutions based on your warehouse dimensions, cargo specifications (weight, size), throughput requirements, and budget—ensuring optimal performance and space utilization.

Absolutely. The Automated Pallet Racking system supports seamless integration with most existing WMS, ERP, and MES systems. Our technical team ensures smooth data synchronization and workflow alignment.

Yes. All components adhere to global standards such as FEM (European Material Handling Federation), DIN (German Institute for Standardization), ISO (International Organization for Standardization), and CE certification—guaranteeing safe and reliable operation worldwide.

Designed for enterprises pursuing high efficiency, high-density storage, and low operational costs, it is an ideal choice for building "lights-out" warehouses and achieving Industry 4.0 upgrades. We are committed to providing global customers with stable, reliable, and technologically advanced automated warehousing solutions. |

|

Pallet Rack Pallet Rack |  Longspan Rack Longspan Rack | ||

Mezzanine Mezzanine |  Very Narrow Aisle Rack Very Narrow Aisle Rack |  Shuttle Radio Rack Shuttle Radio Rack |  Automated Storage Automated Storage |

Wire Mesh Decking Wire Mesh Decking |  Wire Mesh Container Wire Mesh Container |  Steel Pallet Steel Pallet |  Stackable Metal container Stackable Metal container |

content is empty!