- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

CTU (Case Transport Unit) Racking is an intelligent storage unit designed for fully automated "Goods-to-Robot" processes. It functions as a standardized "mobile bin" that robots can directly operate on, serving as the core foundation for "lights-out" unmanned operations in warehouses. The CTU is no longer just a container moved by people or robots; it is the direct target of automated equipment (such as AGVs and robotic arms) for storage and retrieval tasks, enabling end-to-end automation from the warehouse to the production line.

| Availability: | |

|---|---|

| Quantity: | |

The CTU Racking (Case Transport Unit Racking) is a cutting-edge Goods-to-Robot system that redefines automated storage and retrieval for modern warehouses and manufacturing facilities. As the core of "lights-out" unmanned operations, this intelligent CTU racking functions as a standardized, robot-operable "mobile bin"—eliminating manual intervention and enabling end-to-end automation from warehouse storage to production line feeding. Designed for seamless integration with AGVs, robotic arms, and warehouse management systems (WMS), the high-density automated storage solution maximizes space utilization while ensuring rapid, precise handling of goods. With built-in digital twin technology, robot-friendly design, and compliance with global standards (FEM, DIN, ISO), our CTU Racking is the ideal choice for smart manufacturing, e-commerce fulfillment centers, and high-throughput logistics operations seeking to boost efficiency and reduce labor dependency.

The CTU Racking features tight dimensional tolerances and a robust structure, providing a stable physical interface for AGV transport and robotic arm picking. This ensures consistent, error-free interactions between automation equipment and the racking, minimizing downtime.

As the smallest handling unit in automated workflows, Goods-to-Robot CTU Racking directly interfaces with robotic arms, automated sorters, and AGVs—eliminating human labor for storage, retrieval, and material transfer. This enables 24/7 "lights-out" warehouse operations.

Each intelligent CTU rack is equipped with integrated RFID or QR codes, creating an accurate digital twin in the WMS. This enables real-time location tracking, closed-loop command issuance, and status feedback, enhancing inventory traceability.

The standardized design of CTU Racking allows safe, vertical stacking in AS/RS (Automated Storage and Retrieval Systems), maximizing the use of valuable warehouse height. It increases storage density by up to 50% compared to traditional bin storage.

Our automated CTU racking integrates seamlessly with WCS (Warehouse Control Systems), WMS, and third-party automation equipment (e.g., robotic arms, AGVs). This makes it a flexible module for building scalable, end-to-end automated solutions.

| Key Features | |

Robot-Friendly Interface | Precise dimensional tolerances and robust structure provide a stable and reliable physical interface for AGV transport and robotic arm picking. |

Enables Process Unmannedization | As the smallest handling unit in an automated system, it interfaces directly with equipment like robotic arms and automated sorters, eliminating human intervention |

Digital Twin Carrier | With integrated RFID or QR codes, each CTU is an accurate digital twin in the system, enabling closed-loop command issuance and status feedback. |

High-Density Stacking Storage | Standardized design allows for safe, high-density stacked storage in AS/RS, maximizing the use of valuable automated storage space. |

Seamless System Integration | Designed to work in harmony with WCS and automated equipment, it is the ideal module for building flexible automation solutions. |

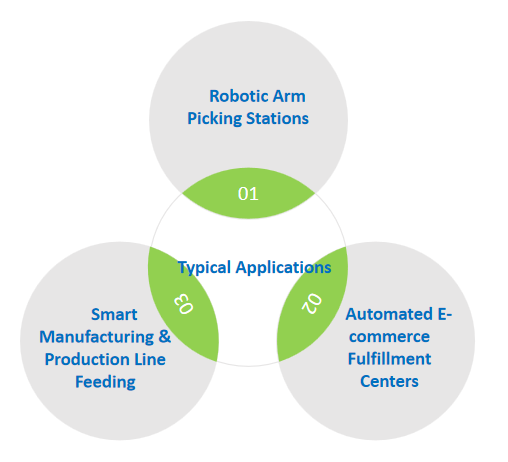

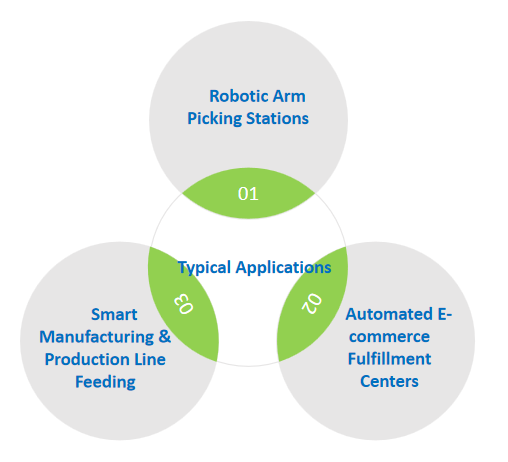

CTU Racking automates the delivery of components (e.g., electronic parts, mechanical components) to production lines. Robotic arms retrieve CTUs directly, ensuring just-in-time feeding and reducing production delays.

E-commerce brands use Goods-to-Robot CTU Racking for order picking and sorting. The system’s high-density storage and rapid retrieval cut order processing time by 40%, supporting peak-season demand.

Intelligent CTU Racking is the backbone of "lights-out" warehouses, enabling 24/7 operation without human intervention. It integrates with AGVs to move goods between storage, sorting, and shipping zones seamlessly.

Logistics providers rely on CTU Racking for high-volume material handling, such as distribution centers and cross-docking facilities. The digital twin technology ensures accurate inventory tracking and reduces shipping errors.

CTU Racking acts as a robot-operable "mobile bin" that requires no manual handling. It integrates with AGVs and robotic arms for storage/retrieval, while the digital twin system provides real-time data to the WMS—eliminating the need for human oversight.

Yes! Our automated CTU racking is designed for seamless integration with most leading WMS and WCS platforms. Our engineering team provides custom APIs and configuration support to ensure compatibility.

With proper maintenance, CTU Racking has a lifespan of 10–15 years. The high-strength material and corrosion-resistant finish protect against wear, while replaceable components (e.g., identification tags) extend usability.

Pallet Rack Pallet Rack |  Longspan Rack Longspan Rack | ||

Mezzanine Mezzanine |  Very Narrow Aisle Rack Very Narrow Aisle Rack |  Shuttle Radio Rack Shuttle Radio Rack |  Automated Storage Automated Storage |

Wire Mesh Decking Wire Mesh Decking |  Wire Mesh Container Wire Mesh Container |  Steel Pallet Steel Pallet |  Stackable Metal container Stackable Metal container |

The CTU Racking (Case Transport Unit Racking) is a cutting-edge Goods-to-Robot system that redefines automated storage and retrieval for modern warehouses and manufacturing facilities. As the core of "lights-out" unmanned operations, this intelligent CTU racking functions as a standardized, robot-operable "mobile bin"—eliminating manual intervention and enabling end-to-end automation from warehouse storage to production line feeding. Designed for seamless integration with AGVs, robotic arms, and warehouse management systems (WMS), the high-density automated storage solution maximizes space utilization while ensuring rapid, precise handling of goods. With built-in digital twin technology, robot-friendly design, and compliance with global standards (FEM, DIN, ISO), our CTU Racking is the ideal choice for smart manufacturing, e-commerce fulfillment centers, and high-throughput logistics operations seeking to boost efficiency and reduce labor dependency.

The CTU Racking features tight dimensional tolerances and a robust structure, providing a stable physical interface for AGV transport and robotic arm picking. This ensures consistent, error-free interactions between automation equipment and the racking, minimizing downtime.

As the smallest handling unit in automated workflows, Goods-to-Robot CTU Racking directly interfaces with robotic arms, automated sorters, and AGVs—eliminating human labor for storage, retrieval, and material transfer. This enables 24/7 "lights-out" warehouse operations.

Each intelligent CTU rack is equipped with integrated RFID or QR codes, creating an accurate digital twin in the WMS. This enables real-time location tracking, closed-loop command issuance, and status feedback, enhancing inventory traceability.

The standardized design of CTU Racking allows safe, vertical stacking in AS/RS (Automated Storage and Retrieval Systems), maximizing the use of valuable warehouse height. It increases storage density by up to 50% compared to traditional bin storage.

Our automated CTU racking integrates seamlessly with WCS (Warehouse Control Systems), WMS, and third-party automation equipment (e.g., robotic arms, AGVs). This makes it a flexible module for building scalable, end-to-end automated solutions.

| Key Features | |

Robot-Friendly Interface | Precise dimensional tolerances and robust structure provide a stable and reliable physical interface for AGV transport and robotic arm picking. |

Enables Process Unmannedization | As the smallest handling unit in an automated system, it interfaces directly with equipment like robotic arms and automated sorters, eliminating human intervention |

Digital Twin Carrier | With integrated RFID or QR codes, each CTU is an accurate digital twin in the system, enabling closed-loop command issuance and status feedback. |

High-Density Stacking Storage | Standardized design allows for safe, high-density stacked storage in AS/RS, maximizing the use of valuable automated storage space. |

Seamless System Integration | Designed to work in harmony with WCS and automated equipment, it is the ideal module for building flexible automation solutions. |

CTU Racking automates the delivery of components (e.g., electronic parts, mechanical components) to production lines. Robotic arms retrieve CTUs directly, ensuring just-in-time feeding and reducing production delays.

E-commerce brands use Goods-to-Robot CTU Racking for order picking and sorting. The system’s high-density storage and rapid retrieval cut order processing time by 40%, supporting peak-season demand.

Intelligent CTU Racking is the backbone of "lights-out" warehouses, enabling 24/7 operation without human intervention. It integrates with AGVs to move goods between storage, sorting, and shipping zones seamlessly.

Logistics providers rely on CTU Racking for high-volume material handling, such as distribution centers and cross-docking facilities. The digital twin technology ensures accurate inventory tracking and reduces shipping errors.

CTU Racking acts as a robot-operable "mobile bin" that requires no manual handling. It integrates with AGVs and robotic arms for storage/retrieval, while the digital twin system provides real-time data to the WMS—eliminating the need for human oversight.

Yes! Our automated CTU racking is designed for seamless integration with most leading WMS and WCS platforms. Our engineering team provides custom APIs and configuration support to ensure compatibility.

With proper maintenance, CTU Racking has a lifespan of 10–15 years. The high-strength material and corrosion-resistant finish protect against wear, while replaceable components (e.g., identification tags) extend usability.

Pallet Rack Pallet Rack |  Longspan Rack Longspan Rack | ||

Mezzanine Mezzanine |  Very Narrow Aisle Rack Very Narrow Aisle Rack |  Shuttle Radio Rack Shuttle Radio Rack |  Automated Storage Automated Storage |

Wire Mesh Decking Wire Mesh Decking |  Wire Mesh Container Wire Mesh Container |  Steel Pallet Steel Pallet |  Stackable Metal container Stackable Metal container |